Advanced Materials & Mechanics Laboratory

Ceramic powder manufacturing by die compaction and pressureless sintering

Turbine blade manufacturing by Hot Isostatic Pressing (H.I.P)

Finite Element Analysis of Teeth Remedy

Teeth model for finite element modeling

First principal stress distribution

Third principal stress distribution

Effective stress distribution

CRYSTAL PLASTICITY IN MECHANICAL EXPERIMENTS & FEM ANALYSIS

•Experimental and numerical investigation of deformation behavior of an aluminum multi-crystal during simple shear

Crystal Plasticity FEM Result (ABAQUS)

Experimental result

CRYSTAL PLASTICITY IN MECHANICAL EXPERIMENTS & FEM ANALYSIS

-

Influence of Unique Directionality of Specimen

Deformation mode is different according to the unique direction of material

The effect on the deformation mode is more directional than the load

Pile-up Patterns of Single Crystals

Research Field

In AMML, a room temperature and high temperature constitutive model was developed for predicting the densification behavior using powder, and it was applied to the finite element analysis (FEM) and compared with the experimental data. The optimization process is applied to the analysis and design of the molding process.

*Main Research field*

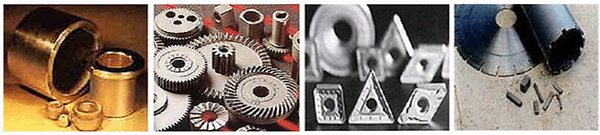

- Powder Metallurgy

- Nano Indentation

- Crystal Plasticity

- Pile-up Patterns of Single Crystals

Near-Net Shape of Powder materials

[Research objective]

• Predicts the shape distortion of products

• Evaluate the strengths and fracture parameters

Analysis of Plastic Behavior for Single Crystal Level Superalloy (NiAl3) (CPFEM) - Doosan Heavy Industries & Construction

Requires long fatigue life and good physical properties (high melting point, excellence in creep) that can withstand high temperatures.

:Using single crystal based Nickel Base Single Crystal (NBSX) super-alloy for meeting requirements

-> Crack propagation and fatigue life prediction required for consumable Turbine blade

Elasto-Plastic Behavior of Single Crystals Affecting Crystal Orientation

: Form a crystal lattice for a specific direction in a solid material

: Shear decomposition stress and dislocation plasticity on slip plane considering crystal orientation

-> Effect on crack nucleation

-> Local crack effect on cyclic loading

(Prajwal A. Sabins et al. 2013, Nalla et al. 2002)